I. Introduction: The Invisible Skeleton of Garments

Have you ever wondered what gives a structured blazer its crisp silhouette or a delicate blouse its subtle shape without adding stiffness? The secret often lies not in the outer fabric, but in a hidden foundational layer known as interlining. This crucial component acts as the "invisible skeleton" of a garment, providing support, enhancing durability, and defining the final form. It is the unsung hero that ensures our clothes not only look good but also maintain their structure over time. Among the various types available, one category stands out for its unique balance of flexibility and stability. This brings us to the focus of our discussion: what is Nylon Nonwoven Interlining Series 8? This specific series represents a key innovation in this essential field of garment construction.

II. Core Definition: Deconstructing the Basic Composition of Series 8

To fully appreciate the capabilities of Nylon Nonwoven Interlining Series 8, it is essential to break down its name and understand the fundamental elements that constitute this material. Each part of its nomenclature points to a specific characteristic that contributes to its overall performance. This series is not defined by a single attribute, but by the synergistic combination of its base material, its manufacturing structure, and its classification within a product family.

Understanding the Components

First, the term Nylon refers to the primary fiber used in the base fabric. Nylon, as a synthetic polymer, is renowned for its exceptional strength-to-weight ratio and outstanding elasticity. In the context of interlinings, this translates to a fusible material that can stretch and recover along with the outer garment fabric, ensuring that the bond remains intact during movement and does not restrict the drape or feel of the apparel. This inherent flexibility makes it an ideal choice for fabrics that require a degree of give.

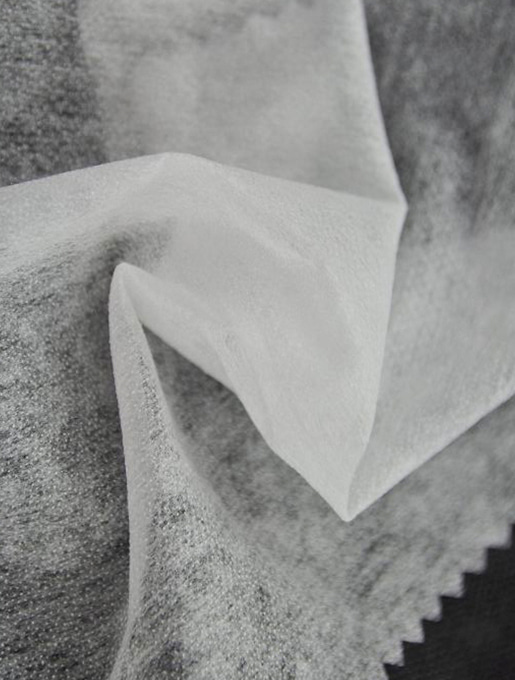

Second, the designation Nonwoven describes the manufacturing process of the base cloth. Unlike traditional woven or knitted textiles, nonwoven fabrics are produced by bonding or felting fibers together through mechanical, chemical, or thermal processes. This method creates a web-like structure that is inherently lightweight, uniform, and resistant to fraying. For interlinings, a nonwoven structure offers excellent dimensional stability and a consistent bonding surface, which is crucial for a smooth fusing process.

Finally, Series 8 typically indicates a specific product line or grade within a manufacturer's portfolio. This classification often groups interlinings that share a common set of baseline specifications, such as standard weight ranges, standard thickness, or a consistent performance profile. It serves as a convenient identifier for a particular category of interlining that has been engineered for a certain class of applications.

Typical Parameter Range within Series 8

| Parameter | Lightweight Version (e.g., 808) | Medium-Weight Version (e.g., 818) | Heavyweight Version (e.g., 828) | Common Test Standard |

|---|---|---|---|---|

| Basis Weight (Grammage) | 20 - 30 g/m² | 31 - 45 g/m² | 46 - 60 g/m² | ISO 3374 |

| Thickness | 0.15 - 0.25 mm | 0.26 - 0.40 mm | 0.41 - 0.55 mm | ISO 5084 |

| Fusing Temperature | 130 - 150 °C | 140 - 160 °C | 150 - 170 °C | ISO 12138 |

| Key Characteristic | Ultra-soft hand feel, suitable for sheer fabrics. | Balanced drape and stability, all-purpose. | High stiffness and support for structured areas. | - |

In summary, Nylon Nonwoven Interlining Series 8 is a category of fusible material constructed from a web of nylon fibers, which is then activated by heat to bond with garment fabrics. The "Series 8" designation helps users quickly identify a family of products that offer a predictable set of properties, with the specific grade being selected based on the precise requirements of the garment being constructed.

III. Key Characteristics: Why Series 8 Stands Out

The true value of Nylon Nonwoven Interlining Series 8 is revealed not just in its composition, but in its performance. This series distinguishes itself from other interlining categories through a combination of engineered characteristics that directly address the demands of modern, high-quality garment production.

1. Superior Bonding and Hand Feel: The Role of Double Dot Coating

A foundational feature that elevates the performance of Series 8 is the prevalent use of the double dot coating method. This advanced adhesive application technique involves precisely printing a pattern of thermoplastic resin dots onto the base nonwoven fabric, followed by a second, overlapping layer of dots. This creates a robust, yet flexible, adhesive network. The primary advantage of this system is its excellent penetration and bonding capability. During the fusing process, the resin melts and flows through the base nonwoven, anchoring itself securely, while simultaneously bonding with the face fabric without striking through (bleeding) to the right side. This results in a remarkably strong peel strength that withstands stress and repeated laundering. Crucially, because the adhesive is applied in a discrete pattern rather than as a continuous film, the natural softness and drape of the nylon nonwoven base are largely preserved, yielding a final product with a soft and natural hand feel that does not compromise the character of the outer fabric.

2. Dimensional Stability: Excelling as a Low Heat Shrinkage Interlining

For any interlining, maintaining its size and shape through the high-heat fusing process and subsequent care is paramount. This is where Series 8 truly excels, establishing itself as a low heat shrinkage nylon interlining. The nonwoven nylon substrate itself has inherently good resistance to thermal contraction. Furthermore, the manufacturing process for this series typically includes thermal setting treatments that pre-stabilize the fabric. This low shrinkage characteristic is critical for preventing garment distortion, such as bubbling, puckering, or warping of seams and panels, which can occur if the interlining shrinks at a different rate than the face fabric after fusing or washing. This exceptional stability ensures that the precise shape and structure designed into a collar, cuff, or placket are maintained throughout the garment's lifecycle, making it a reliable foundation for precision tailoring.

3. Durable Performance: The Assurance of a Washable Interlining

The ultimate test for any garment component is its ability to endure real-world use and care. Series 8 is specifically engineered to be a highly washable nylon nonwoven interlining. Its performance is a result of the combined strengths of its components: the resilient nylon fibers, the stable nonwoven structure, and the strong bond created by the double-dot adhesive. Nylon itself is resistant to mildew and deterioration in damp conditions, while the robust bond ensures the interlining remains firmly fused to the fabric, resisting delamination even after aggressive mechanical action in washing machines. This makes it an ideal choice for a wide range of apparel that requires frequent laundering, from formal shirts to uniform blouses, ensuring the garment's integrity and appearance are preserved over time.

Performance Metrics Comparison

| Key Characteristic | Performance Metric | Typical Series 8 Performance | Generic Interlining Baseline (Approx.) | Common Test Standard |

|---|---|---|---|---|

| Bonding Strength | Peel Strength (after fusing) | 8 - 12 N/5cm | 5 - 8 N/5cm | ISO 11339 |

| Dimensional Stability | Dimensional Change (after washing, warp & weft) | -1.0% to +0.5% | -2.5% to +1.5% | ISO 5077 |

| Washability | Peel Strength (after 5 washes) | > 7 N/5cm | < 5 N/5cm | ISO 6330 / ISO 11339 |

| Hand Feel | Stiffness (Bending Length) | 20 - 35 mm | 30 - 50 mm | ISO 9073-7 |

In conclusion, the Nylon Nonwoven Interlining Series 8 stands out because it delivers a powerful combination of a strong but soft bond, exceptional dimensional integrity, and proven durability through washing. It is this triad of high-performance characteristics—enabled by double dot coating, low heat shrinkage, and a washable construction—that provides garment manufacturers with the confidence to produce high-quality, long-lasting apparel.

IV. Primary Application Scenarios: Where Series 8 Excels

The technical characteristics of Nylon Nonwoven Interlining Series 8—its flexibility, stable structure, soft hand feel, and durability—are not developed in a vacuum. They are precisely engineered to meet the rigorous demands of specific applications within the garment industry. This series has found its niche by solving common construction challenges, establishing itself as a fundamental nylon nonwoven interlining for garments that require a perfect balance of support, comfort, and longevity.

The application of Series 8 is primarily dictated by the weight and stiffness grade selected, making it a versatile tool for a designer's or manufacturer's toolkit. Its core function is to provide controlled reinforcement, prevent distortion in stress areas, and maintain the desired shape without adding undue bulk or stiffness. The inherent low heat shrinkage property is critical here, as it guarantees that components like collars and cuffs, which are precision-cut and fused, will not warp or pucker after the first wash, preserving the garment's professional appearance. Furthermore, its classification as a washable nylon nonwoven interlining makes it indispensable for any apparel destined for frequent home or commercial laundering, ensuring the bond between the interlining and the face fabric remains secure over dozens of wash cycles.

Application Guide by Garment Type

| Garment Application Zone / Type | Recommended Series 8 Grade | Key Property Utilized | Benefit & Outcome |

|---|---|---|---|

| Blouse & Dress Plackets | Lightweight (e.g., 20-30 g/m²) | Soft hand feel, flexibility | Prevents fabric curling, provides clean closure line without stiffness, maintains drape. |

| Delicate Sheer Fabrics | Lightweight (e.g., 20-30 g/m²) | Soft hand feel, fine nonwoven structure | Provides minimal reinforcement without being visible through the fabric, preventing seam puckering. |

| Shirt Collars & Cuffs | Medium-Weight (e.g., 31-45 g/m²) | Dimensional stability, washability, firm bond | Maintains crisp, defined shape through repeated washing and wear; resists curling and wilting. |

| Lightweight Jacket Facings | Medium-Weight (e.g., 31-45 g/m²) | Stability, durability, balanced drape | Provides body and structure to the front of a jacket without the weight of a heavy canvas, improving comfort. |

| Structured Tops (Yoke & Sleeve Heads) | Medium to Heavyweight (e.g., 36-50 g/m²) | Support, stability | Reinforces the yoke and creates a subtle roll in the sleeve head for a polished silhouette. |

| Embroidery Backing | Lightweight (e.g., 20-30 g/m²) | Stable nonwoven base, washable nature | Prevents fabric distortion during embroidery and provides a clean finish; remains stable in the final product. |

In summary, Nylon Nonwoven Interlining Series 8 truly shines in the creation of high-quality, durable blouses, dresses, shirts, and structured lightweight outerwear. Its ability to provide invisible support, maintain critical shapes, and withstand the rigors of laundering makes it an indispensable component for producing garments that are built to last while offering superior comfort and a refined appearance.

V. Conclusion

In summary, Nylon Nonwoven Interlining Series 8 represents a sophisticated fusion of material science and practical application within the textile industry. Through our detailed exploration, it becomes clear that this series is not merely a simple accessory but an engineered component that significantly elevates garment quality and performance. Its fundamental composition—combining the resilient elasticity of nylon fibers with the uniform stability of a nonwoven structure—creates an ideal substrate. When this base is enhanced with advanced double dot coating technology, the result is a product that delivers both exceptional bonding strength and a remarkably soft hand feel, addressing the classic trade-off between durability and comfort.

The defining characteristics of this series are what truly set it apart in the marketplace. Its performance as a low heat shrinkage nylon interlining ensures critical garment components maintain their precise shape and integrity through the high-heat fusing process and beyond. This intrinsic stability, coupled with its proven reliability as a washable nylon nonwoven interlining, guarantees that the garments it supports can withstand the rigors of repeated laundering without succumbing to delamination, distortion, or bubbling. These properties collectively establish Series 8 as a cornerstone for producing durable, high-quality apparel. Its primary identity as a premium nylon nonwoven interlining for garments is firmly rooted in this consistent delivery of key benefits across a wide spectrum of applications, from delicate blouses to structured shirt collars.

Summary of Value Proposition

| Core Aspect | Technical Foundation | Resulting Key Property | Primary Application Benefit |

|---|---|---|---|

| Material & Structure | Nylon fibers bonded in a nonwoven web. | Elasticity, softness, and uniform stability. | Provides flexible support that moves with the garment and wearer. |

| Bonding Technology | Precision-applied double dot coating of thermoplastic resin. | Strong peel strength without compromising hand feel; no strike-through. | Ensures durable fusing for long-lasting garment structure while preserving fabric drape. |

| Durability & Stability | Thermally-set fibers and robust construction. | Low heat shrinkage and excellent washability (resistance to washing and dry cleaning). | Maintains garment shape and integrity over time, ensuring a professional appearance after repeated care. |

| Product Versatility | Availability in a range of weights (e.g., 20-60 g/m²) within the series. | Tailored support from ultra-soft to firm. | Suitable for a vast array of applications, from delicate sheers to structured casual wear. |

Ultimately, Nylon Nonwoven Interlining Series 8 stands as a testament to the critical role that hidden components play in the world of textiles. It is the unseen element that empowers designers and manufacturers to achieve their vision for apparel that is not only aesthetically pleasing upon first purchase but also built to endure. By delivering a reliable combination of flexibility, stability, and durability, this interlining series secures its position as an indispensable asset in the creation of garments that successfully blend quality craftsmanship with long-term consumer satisfaction.

Frequently Asked Questions (FAQ)

- What types of garments is Nylon Nonwoven Interlining Series 8 best suited for?

This series is exceptionally versatile and is ideally suited for a wide range of apparel that requires a blend of softness, shape retention, and durability. Its most common applications include blouses, dresses, and shirt collars and cuffs where it provides structure without stiffness. It is also excellent for use with delicate and sheer fabrics, as well as for reinforcing areas like plackets and embroidery, ensuring the garment maintains a clean, professional look after repeated washing. - How does the double dot coating technology used in Series 8 improve the final garment?

The double dot coating is a advanced adhesive application method that prints two layers of resin dots onto the interlining base. This technology is crucial for creating a strong, durable bond with the face fabric during fusing, preventing delamination. More importantly, because the adhesive is applied in a discrete pattern rather than a solid layer, it allows the interlining and the outer fabric to remain flexible and soft. This results in a superior, more natural hand feel, which significantly enhances the comfort and perceived quality of the final garment. - As a manufacturer with a long history, how does Jiaxing Rainbow (UBL) Interlining Co., Ltd. ensure the consistent quality of its interlinings like Series 8?

With extensive experience since 1995 in the professional design and production of fusible interlinings, Jiaxing Rainbow (UBL) Interlining Co., Ltd. places a strong emphasis on technological innovation and process control. As one of China's initial pioneers in double-dot coating manufacturing, we have built our expertise on advanced production equipment and a rigorous focus on R&D. This long-term commitment to high technology and precision engineering allows us to maintain strict consistency in key performance metrics—such as peel strength, dimensional stability, and washability—across every batch of our products, including the Nylon Nonwoven Interlining Series 8. Our dedication to being "practical, professional, and forging ahead" ensures we deliver reliable and high-performing solutions to our customers worldwide.

English

English Español

Español Türk

Türk 简体中文

简体中文