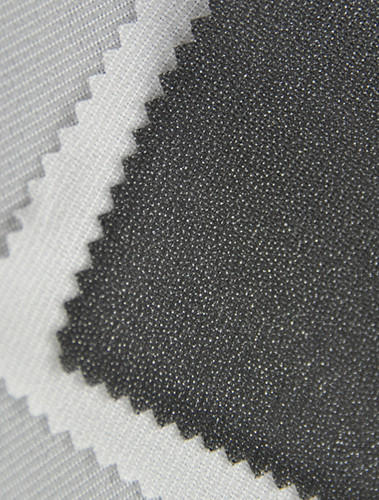

Shirt Interlining is an additional layer that is added to a piece of clothing fabric in order to add thickness, firmness and strengthen it. It is used mostly in collars, cuffs and pats to support the shape of the fabric, and also to reduce its tendency to wrinkle. It is also used to give a thicker base for embroidery. Unlike interfacing which is often hand placed or fused to the fabric, interlining is cut in an entire panel and then placed to the wrong side of the main piece of fabric. This is more common in couture work.

There are numerous extraordinary kinds of interlining to be had inside the market, from bonded to non-fusible. Fusible interlining is the maximum generally used, accounting for about ninety consistent with cent of all clothing. This kind is fused to the fabric with the aid of heat, which gives it a stronger bond. It can also be stitched to the material. Non-fusible interlinings are normally used in extra delicate or unique fabric consisting of georgette, silk and crepe.

The type of lining that is best proper for a selected garment will rely on the type of fabric in addition to its coloration and function. For instance, a light color blouse could in all likelihood advantage from being covered with a white or similar coloured lining in an effort to prevent discolouration of the collar after repeated washings. The same principle applies to using interlining in jackets. A jacket with a darker shade or print could possibly want to be covered with a lighter colour or pattern if you want to make sure that the lining doesn’t stand out too much from the relaxation of the jacket.

One of the nice approaches to make certain a terrific best interlining is to ensure that it's miles fused well. This may be achieved by using making sure that the temperature and pressure are correct for the particular fusing system being used. There are a number of issues which can get up if fusing isn't executed well. These consist of coloration alternate of the liner, static charge, bubbles inside the collar, loss of adhesion between the liner and the shell cloth and adhesive strike through.

To keep away from these troubles, it is vital to use a fusing device that is designed to work with the precise form of lining. There are a number of unique styles of fusing machines available on the market, from basic to excessive cease.

English

English Español

Español Türk

Türk 简体中文

简体中文