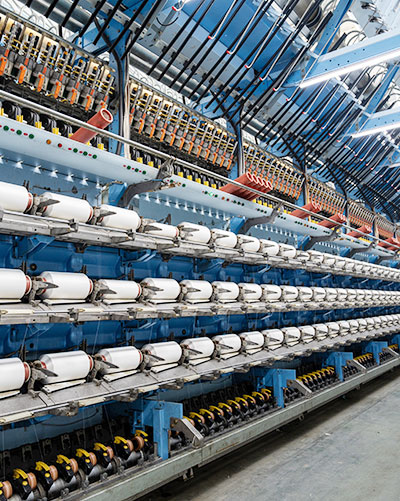

1.Texturizing

Texturing, as the starting point of production, employs false twist texturing technology to transform polyester filament yarn without twist (POY) into DTY stretch yarn with both fluffiness and elasticity through heating, stretching, and mechanical twisting. This process increases fiber fluffiness by 30%, laying the foundation for subsequent fabric elasticity.