Enhancing Every Garment

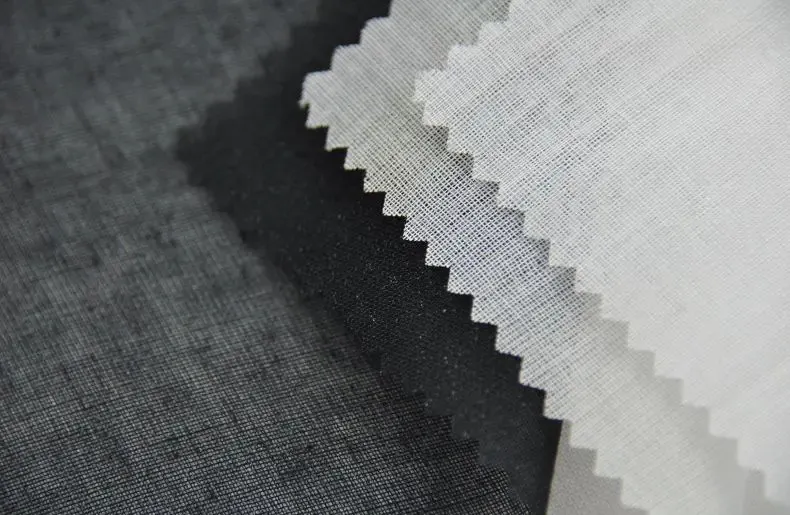

Garment Woven Interlining interlining Development Today, from the 1th generation of cotton, hemp, brown and other fabric lining and 2nd generation of black carbon lining wool lining, Mawei liner the 3rd generation of resin lining developed into the modern apparel industry in the field of the 4th generation spinning and Non-woven Hot melt adhesive liner, and high flexible, ultra-thin, environmental protection, health-type, washable, Breathable Advanced Interlining as the 5th generation of new bonded interlining also emerged.Knitted lining, is knitted cloth as the base cloth, after hot melt adhesive coating processing of bonded interlining. Knitted lining and weft-lined lining, warp-lined and weft-lined warp-lined, its performance similar to woven lining, both good with the movement, but also a good drape.The knitted lining, which is an adhesive liner and is a permanent type of adhesive liner, is an important part of the 4th generation interlining non-woven and bonded and 5th generation Interlining modified adhesive liner. Due to the characteristics of knitted fabrics, knitted lining becomes with the general adhesive lining different, unique knitted fabric special interlining, mainly used for knitted coat of the predecessor, collar, door lapel, cuffs, hem and bag mouth as well as hakama waist, panties mouth zipper fixed parts, foot hem and other parts, to do local adhesion, played to the reinforcement, protection, Modelling and other functions.

The adhesive liner "with the sticky seam" simplifies the modern garment processing technology, so that the efficiency of industrial production is unprecedentedly improved. Knitted lining as a kind of adhesive lining, it not only gives a good shape of clothing, but also to make clothing more light, thin, soft, very, elastic, Shu, endowed with the colorful aesthetic characteristics of clothing, just right to reflect people's personality requirements for modern clothing style.The knitted lining can be divided into different kinds according to different dividing ways. According to the formation of knitted lining cloth can be divided into warp-lined, weft-lined, non-woven plus seam lining. According to the performance of knitted lining fabric can be divided into: high elastic lining, low elastic lining, four-direction elastic lining, high-support high mesh lining. According to the use of knitted lining can be divided into large body lining, collar lining, door lining, hem lining, cuffs lining, pocket lining, waist lining, panties mouth lining, such as drawing lining.Knitted apparel, especially knitted garments, have many differences from those used in woven fabrics. The most characteristic of knitted fabrics used in knitted garments is multi-directional elongation. Because whether the use of natural fiber fabric or chemical fiber fabric or other interwoven fabrics, due to the coil series, knitted fabric is very obvious scalability.

Therefore, the choice and use of knitted fabrics with this feature similar or the same adhesive lining, become knitted garments clothing the preferred condition.However, the use of knitted fabrics with the same telescopic characteristics of interlining, not only to consider the stability of knitted fabrics after bonding, and for the design of the needs of modelling, it must be fixed and reinforced, but also require a flexible knitting fabric with different structure of the relatively stable knitted lining, thus controlling the activities of its fabrics. For example: the collar and cuffs of a loose knit suit, to use an easily retractable woven or Non-woven fusible interlining for better results. According to the design purpose of knitted garments and the characteristics of clothing fabrics, it is a key to choose the knitting lining differently. The selected adhesive lining is different, then the performance of the knitted fabric after bonding is not the same. The selection should carefully consider these changes, make careful choice.

Therefore, the use of knitted lining must be clearly understood in the case of knitted fabric and knitted coat characteristics, select the appropriate correct interlining.Knitted lining corresponds to the characteristics of knitted fabrics and knitted garments, should have the performance and quality to meet the needs of knitted apparel, can have a wide range of application adaptability. Its intrinsic quality requirements are as follows: with the dynamic telescopic, full of elasticity, strong fastness, anti-loose, roll edge, breathable, hygroscopic, soft, not easy to peel, good sewing, not easy to deformation after washing. In addition, should also have anti-static, antibacterial, low formaldehyde, health and other properties.Before the primary bonding liner, we must first confirm the 4 conditions of the garment fabric shrinkage, pressing temperature, time and pressure then you can preselection the bonding lining, set the bonding conditions, through testing to demonstrate the correctness of its choice. The main test demonstration is as follows. Confirm the fabric, fibrous tissue which conforms to the clothing design requirements, set the bonding temperature such as natural fiber is, synthetic fibre is. According to the Fabric organization pressure for example, the woven fabric is 0.3kg/cm2 and the knitted fabric is , according to the fabric quality, thickness to determine the adhesive lining, set the pressure of the time refer to the Adhesive liner processing plant specified fabric quality, thickness limit selected interlining, set to conform to the standard adhesion of the adhesive lining pressure hot conditions.