2025-10-13

Interlining — Why Is This Hidden Layer Suddenly in the Spotlight?

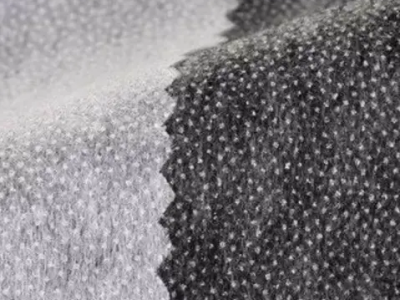

A subtle element of garment construction is gaining renewed attention from designers, home sewists and industry commentators. The extra fabric layer placed against the wrong side of outer materials ha

Learn more