UBL

Enhancing Every Garment

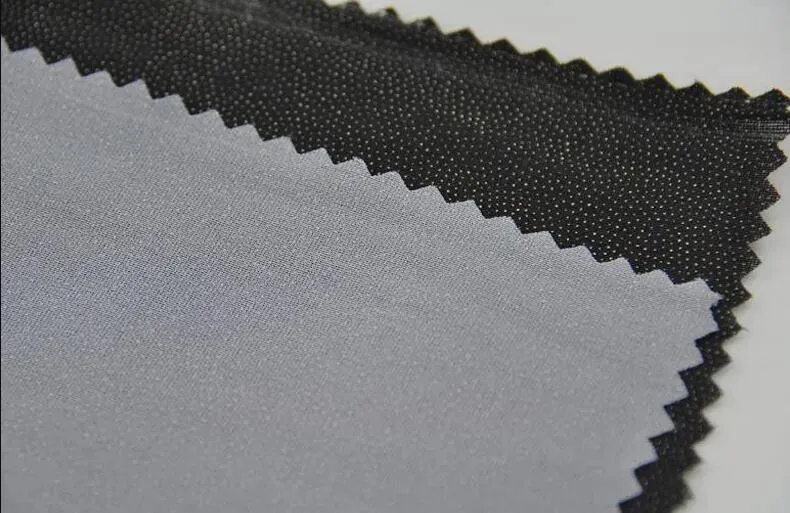

Interlining is a material between clothing fabrics and linings. It is the bones of clothing.” Let’s take a look at the uses of linings: it helps shape, shape, and maintain clothing; enhance the crispness and elasticity of clothing; improve The drape and comfort of the fabric; the reinforcement of specific parts of the garment. If the appearance or style of clothing such as styles and fabrics is the appearance or style of a garment, undoubtedly use a profound term such as "skeleton". It’s a good idea to describe clothing linings. The same reasoning: Faces of different styles naturally have muscles and bones that suit them. The choice of lining is also a big problem. First, we must understand the fabric structure, fiber composition and finishing conditions, and pay special attention to finishing fabric The choice of interlining and bonding conditions.

Master the discoloration of the fabric during high temperature pressing, and do a press discoloration test before application. Master the heat shrinkage rate and shrinkage rate of the fabric during the bonding process. Then according to the processed clothing and surface Different linings can choose different linings. For example, men’s and women’s shirts use polyethylene coated collar linings, which are characterized by excellent washing resistance and a stiff shape. They can be used as main lining, auxiliary lining, cuffs, and placket. Silicone-finished fabrics are made of field type, which has better bonding effect. Outerwear should use polyamide coated outer lining. Choose appropriate varieties according to the thickness of menswear, womenswear and fabrics, suitable for large bodies, collars and bags Covers and other parts.

Fashion, silk clothing can choose PA or PES (polyester) coating fashion lining, can give the clothing a light, soft, drape and stiff style characteristics. The final consideration is to match the color of the lining with the fabric, especially thinner For the variegated fabrics, you should choose the corresponding color interlining. The heat shrinkage rate of the interlining and the compatibility of the fabric have no big difference. The coating quality of the interlining requires full coating glue spots, no leaks, and no powder. Adhesion. Selection of equipment: For shirt bonding, a roller-type continuous pressing machine is generally used to grasp the difference between the temperature, time, pressure displayed by the pressing machine and the actual temperature, time, and pressure, so as to accurately adjust the process parameters.

The upper and lower pressure plates and the conveyor belt should be used Keep it clean, and there should be no debris, such as thread, flower hair, rubber powder, etc. The pressing conditions require that the pressing conditions must be optimized before mass production to determine the best process conditions; interlining and fabric pressing Peel it off after bonding. If the rubber particles and the lining cloth are evenly distributed, the pressing conditions are appropriate, otherwise the pressing conditions need to be changed before the test; the cloth surface after bonding is smooth, no foam, no glue, strong adhesion High; dry-cleaning and washing resistance tests are carried out after bonding, and the dry-cleaning and washing performances meet the requirements of the clothes made; the bonding effect can show the style and characteristics of the clothes.