UBL

Enhancing Every Garment

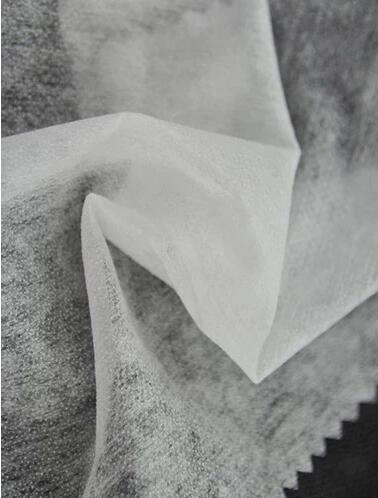

Non-woven Fusible Lining is an inexpensive way to reinforce clothing. Non-woven fusible interfacing can be reusable and machine washable. The HTC-White fusible non-woven interfacing is made from 100% polyester and measures three yards by fifteen inches. This interfacing provides light to moderate support to detailed areas and is suitable for most blouse fabrics. It is also an economical choice for reinforcing paper patterns.It is important to check the label to be sure that the product you are buying is suitable for the material you are using. The product will feel different once it is fused to your fabric. If it feels stiffer than you expected, it's probably too stiff. However, there are some things you can do to ensure that you don't ruin your fabric by overheating it.

Nylon Nonwoven Interlining Series 8

Non-woven fusible interfacing is available in a variety of weights and types. The lightweight variety is suitable for lightweight materials, while the heavy-duty variety is better for heavier-weight fabrics, such as outerwear. Both types of interfacing are suitable for various projects, whether they are home decor or garment-making.The non-woven type is more flexible than its counterpart. It is easy to cut. Since non-woven interfacing is flexible, it can be cut in any direction. If it is cut into multiple pieces, you won't end up wasting too much of the material. On the other hand, woven interfacing behaves like fabric, while it looks stiffer. The non-woven variety can also leave creases and crinkles on the right side of the fabric.

Fusible interfacing is easy to use and can be found at your local fabric store. It requires fewer steps than sew-in interfacing and is available in web form, which has a loose weave. It is available in several weights including lightweight, medium and sheer. It does not have a grain, making it easy to cut in any direction.To use fusible interfacing, place it on the wrong side of the facing fabric. The adhesive side should be on the fabric that's on the grain, which can be easily determined by looking at the selvages. Then place the facing fabric on top of the fusible interfacing.There are many types of fusible interfacing available, and they all offer similar features.

The only difference is that fusible interfacing is usually glued onto the wrong side of a fabric, while sew-in interfacing must be sewn into place. Sew-in interfacing is more appropriate for fabrics that won't take heat well or have a loose weave or texture.Knit and non-woven fabrics may need different ironing temperatures to achieve the desired results. Knit fusible interfacing, on the other hand, is made from fibers that have been woven together. Knit and woven fabrics tend to behave similarly when fused, but they will also appear stiffer.Knit interfacing is a useful tool when making a fusible lining. It can be used in a variety of ways, from soft shaping to firm support. It is typically made of polyester and is available in a variety of colors and sizes. It is generally available from fabric stores or from the manufacturer of your garment.