1.Lightweight Yet Strong: The Material Revolution of Non-woven Lining

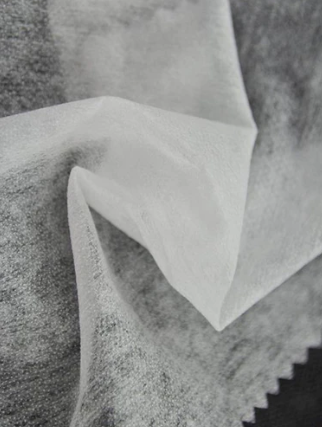

1.1 Redefining Structural Support with Featherweight Construction

Traditional linings often require thickness to deliver strength, which leads to bulkiness and reduced flexibility. Non-woven Lining challenges this norm by offering exceptional durability and tensile strength while maintaining a lightweight form, making it a breakthrough choice for designers who seek structural integrity without compromising comfort.

1.2 Smart Composition for Optimal Form Retention

Using a combination of physical entanglement and chemical bonding, Non-woven Lining maintains its shape under pressure, friction, or bending. This unique construction ensures that end products—be it apparel, bags, or upholstery—retain their form and function over time, enhancing overall user experience.

1.3 Balancing Aesthetics and Engineering in Modern Design

In an age where users demand visual appeal alongside performance, Non-woven Lining delivers on both fronts. Its smooth, adaptable surface complements various outer materials while adding structural coherence, enabling designers to bring to life sleek, lightweight creations without technical compromise.

2.Innovation Beyond the Weave: How Technology Unlocks Versatility

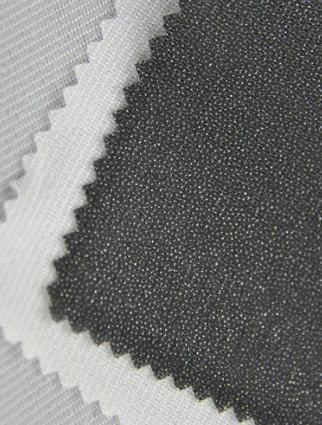

2.1 Non-woven Construction Breaks Thickness-Strength Dependency

Unlike traditional woven linings that rely on yarn density and layering to achieve strength, Non-woven Lining leverages modern bonding techniques to maintain strength even at minimal thickness. This reduces unnecessary bulk and allows greater freedom in tailoring and shaping without sacrificing performance.

2.2 Enhanced Breathability Without Sacrificing Integrity

One of the standout benefits of non-woven materials is their breathability. While strong and stable, Non-woven Lining allows for airflow, making it ideal for applications that require both support and ventilation—such as performance wear or interior padding in bags and shoes.

2.3 Precision Engineering Enables Consistent Quality Output

Modern manufacturing methods enable tight control over fiber distribution, thickness, and density, ensuring each roll of Non-woven Lining meets stringent quality standards. This uniformity is critical in mass production, reducing defect rates and maintaining high product consistency across different design lines.

3.Future-Ready and Design-Smart: Meeting the Demands of a Changing Market

3.1 Superior Durability Across Use Cases and Environments

Thanks to its resistance to deformation, tearing, and environmental changes, Non-woven Lining stands up to a wide variety of stresses—from prolonged compression in luggage interiors to repetitive movement in activewear. Its longevity translates into fewer replacements and a more sustainable product lifecycle.

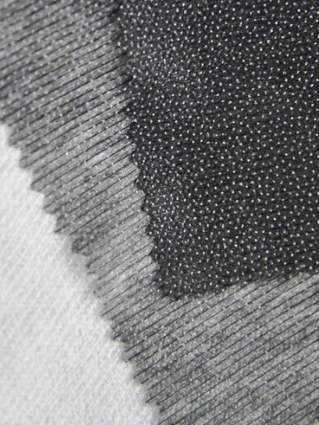

3.2 Seamless Integration into High-Performance Product Lines

Designers across industries—from fashion and home textiles to automotive and accessories—favor Non-woven Lining for its adaptability. It can be layered, laminated, or bonded with other materials, allowing for a customizable foundation that enhances both structural performance and end-user comfort.

3.3 Aligning with Consumer Trends for Lightweight Functionality

Today’s consumers want products that are easy to carry, comfortable to wear, and built to last. Non-woven Lining hits this sweet spot, enabling brands to deliver precisely what modern buyers seek: smart, lightweight, and reliable design built on the strength of innovation.

English

English Español

Español Türk

Türk 简体中文

简体中文