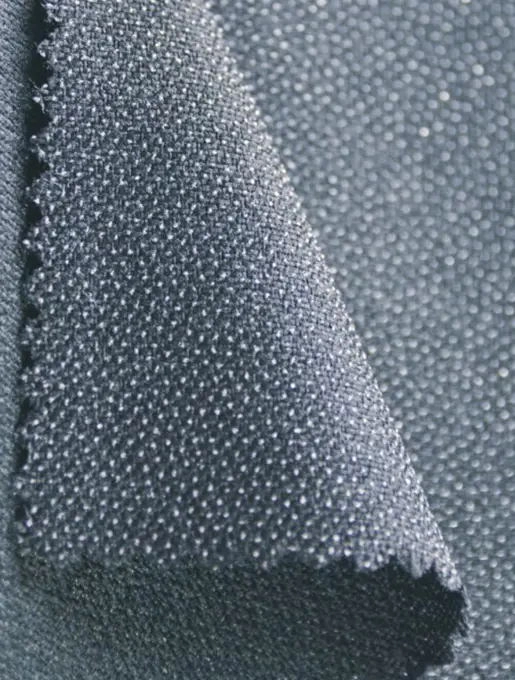

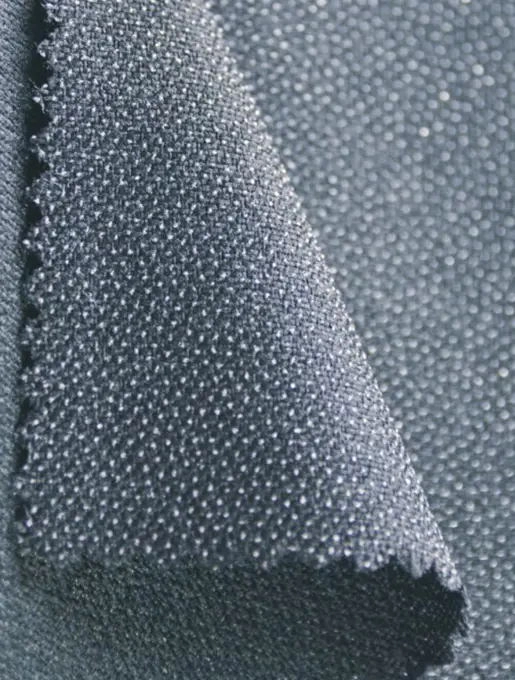

Apparel Fusible Interlining Fabric is a crucial component in the garment manufacturing industry. It is a type of fabric that is attached to the inside of a garment using heat and pressure, providing structure, support, and shape. The interlining fabric is commonly used in collars, cuffs, waistbands, and other areas of the garment where added strength is needed.

Fusible interlining fabrics come in a variety of weights, thicknesses, and compositions, depending on the type of garment and the desired effect. Some common types of fusible interlining fabrics include woven, non-woven, and knit. Each type of fabric has its unique characteristics and properties that make it suitable for specific applications.

Woven fusible interlining fabrics are made of yarns that are woven together to create a stable and durable fabric. These fabrics are commonly used in dress shirts, blouses, and other garments where a crisp and structured look is desired. Woven interlining fabrics are also used in tailored jackets, where they provide support and shape to the lapels and collar.

Non-woven fusible interlining fabrics, on the other hand, are made of fibers that are bonded together using heat and pressure. These fabrics are commonly used in lightweight garments, such as summer dresses and blouses. Non-woven interlining fabrics are also used in sportswear and casual wear, where a softer and more flexible interlining is required.

Knit-fusible interlining fabrics are made of knitted yarns that are bonded together using heat and pressure. These fabrics are commonly used in stretchy and form-fitting garments, such as yoga pants and athletic wear. Knit interlining fabrics are also used in lingerie and swimwear, where a soft and flexible interlining is required.

Fusible interlining fabrics are easy to use and can be applied to the garment using a standard iron or a heat press. The interlining fabric is placed between the garment and the iron, and heat and pressure are applied for a specified time. The heat activates the adhesive on the interlining fabric, which then bonds to the garment.

One of the advantages of using fusible interlining fabric is that it can improve the quality and durability of the garment. The interlining fabric adds stability and support to the garment, reducing the risk of stretching, tearing, and sagging. Additionally, the interlining fabric can improve the appearance of the garment, giving it a more polished and professional look.

In conclusion, Apparel Fusible Interlining Fabric is a crucial component in the garment manufacturing industry. It provides structure, support, and shape to the garment and improves its quality and durability. With a variety of weights, thicknesses, and compositions available, fusible interlining fabrics can be used in a wide range of garments, from dress shirts to yoga pants. Whether you're a professional tailor or a DIY enthusiast, incorporating fusible interlining fabric into your garment-making process can help you create high-quality and long-lasting garments.