Enhancing Every Garment

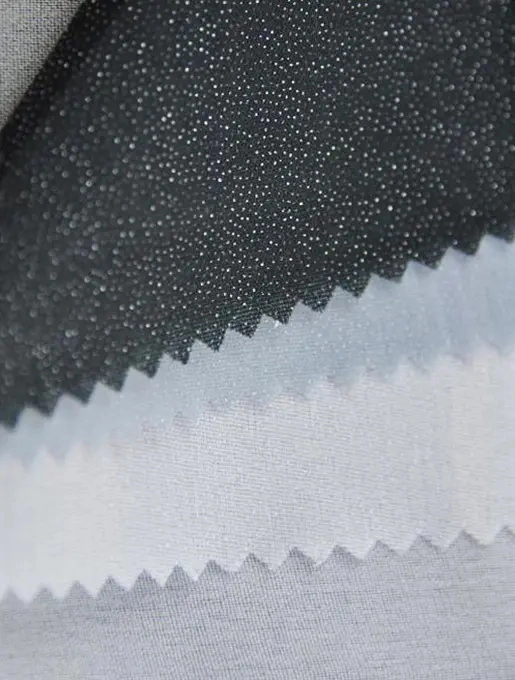

In the world of apparel production, every visible detail matters - from the texture of fabric to the precision of stitching. Yet, hidden beneath the surface lies an element that determines structure, comfort, and longevity: interlining . While often unnoticed by consumers, it plays a vital role in shaping garments, enhancing performance, and ensuring wearability. For procurement specialists, the challenge lies not only in identifying suitable options but also in ensuring suppliers can meet global standards. This guide explores key considerations, purchasing strategies, and the advantages of choosing UBL as a trusted partner.

Behind every well-tailored suit, crisp shirt, or structured coat lies a hidden layer that reinforces shape. Without proper supportive material, collars collapse, cuffs lose definition, and jackets fail to retain form. Procurement managers recognize that long-term product value depends on layers chosen during the sourcing stage. High-quality interlining enhances stability, improves handling during sewing, and ensures consistency across production batches.

The decision to invest time in selection pays off in downstream benefits: smoother workflow, fewer complaints, and stronger consumer trust. Choosing the right option transforms production from a risk-laden process into a streamlined, efficient operation.

1. Fabric Compatibility

Every textile has its own behavior. Lightweight cotton, stretchy knits, and dense wool each require carefully matched support. Misalignment between outer fabric and inner layer results in bubbling, wrinkling, or stiffness. Successful procurement demands thorough testing to ensure seamless blending.

2. Adhesion Quality

Fusible materials depend on consistent bonding. Adhesive resins must activate at the correct temperature without damaging outer cloth. Procurement teams should verify bonding strength under pressing conditions and after repeated laundering.

3. Weight and Thickness

Balancing the weight of hidden layers with outer fabric determines final drape. Lightweight support ensures shirts remain soft and flexible, while heavier options create structure in coats or uniforms. Sourcing managers evaluate handle, thickness, and balance before making bulk commitments.

4. Durability in Care Cycles

Interlining must withstand washing, dry cleaning, and pressing without losing performance. Dimensional stability, shrink resistance, and resilience under stress are critical indicators of reliability.

5. Sustainable Sourcing

Growing awareness of ecological responsibility places pressure on manufacturers to adopt environmentally conscious practices. Buyers who choose sustainable solutions not only meet regulatory requirements but also enhance brand reputation.

| Type | Structure | Typical Uses | Key Benefits |

|---|---|---|---|

| Woven | Yarn-based, strong | Suits, coats, tailored garments | High durability, shape retention |

| Nonwoven | Bonded fibers | Casual wear, mass production | Cost-effective, versatile |

| Knitted | Loop-based, flexible | Stretch fabrics, sportswear | Elasticity, comfort |

| Fusible | Coated with resin | Shirts, collars, cuffs | Easy application, secure adhesion |

| Sew-in | Uncoated, stitched | Traditional tailoring | Natural feel, breathable |

This table highlights how each category serves unique purposes. Understanding distinctions allows procurement professionals to match specific needs with appropriate solutions.

Resin Coating Methods: Uniform coating ensures consistent adhesion. Variations affect performance.

Heat Sensitivity: Materials should activate at safe temperatures without damaging delicate textiles.

Finishing Treatments: Anti-shrink, anti-pilling, or soft-hand finishes enhance value.

Quality Control: Consistent inspection prevents irregularities that might compromise performance.

Procurement specialists who dig deeper into manufacturing processes gain confidence that suppliers can deliver consistency across shipments.

Initial Research: Study potential suppliers, product lines, and service capacity.

Sample Request: Obtain swatches for testing under realistic production conditions.

Compatibility Testing: Apply chosen samples to intended fabrics and evaluate under pressing.

Pilot Production: Run small batches to observe sewing performance and final appearance.

Feedback Analysis: Incorporate input from sewing operators and quality inspectors.

Bulk Ordering: Place larger orders only after validation across steps.

Continuous Review: Maintain communication with suppliers for technical support and product updates.

This structured approach minimizes risk and enhances efficiency, ensuring procurement decisions contribute to long-term success.

The global apparel landscape continues to evolve, driven by shifting consumer expectations and regulatory frameworks. Current trends include:

Eco-Friendly Innovation: Increased demand for recyclable or biodegradable support materials.

Lightweight Solutions: Rising popularity of casual wear drives interest in softer, less rigid options.

Performance Enhancement: Sportswear and uniforms require flexible yet durable support layers.

Digitalization of Supply Chains: Technology improves traceability, ensuring ethical sourcing.

For procurement managers, staying ahead of these trends means selecting suppliers that adapt quickly to industry changes.

Prioritizing Price Over Quality: Low-cost options may fail under production stress.

Skipping Testing Procedures: Ignoring compatibility checks can cause to costly rework.

Neglecting Sustainability Requirements: Non-compliance can restrict access to key markets.

Inconsistent Supplier Communication: Poor coordination increases risk of delays and quality issues.

Avoiding these pitfalls strengthens purchasing strategies and enhances final product value.

Formalwear Tailoring

High-end suits require woven interlining to maintain structure. UBL provides options that deliver sharp lines without bulk, enabling brands to achieve a premium finish.

Shirt Manufacturing

Collars and cuffs depend on fusible options with great adhesion. By supplying consistent quality, UBL helps shirt makers achieve crisp definition across large-scale production.

Sportswear Production

Stretch fabrics demand knitted support. UBL’s flexible solutions allow athletes to enjoy comfort without sacrificing durability.

Casual Wear

Mass-market garments benefit from nonwoven layers. UBL offers cost-effective solutions while ensuring stability during repeated use.

These scenarios demonstrate how correct choices enhance product quality across categories.

UBL positions itself as more than a supplier—it is a partner committed to supporting global apparel businesses. Procurement leaders value:

Wide Portfolio: Multiple categories to suit diverse needs.

Consistent Standards: Strict quality control across every batch.

Technical Guidance: Expert teams assist with selection, testing, and application.

Sustainability Alignment: Responsible practices ensure compliance with modern expectations.

Global Reach: Efficient logistics ensure timely delivery worldwide.

This combination of reliability, expertise, and service excellence sets UBL apart in a competitive market.

By applying these insights, buyers can make informed decisions when sourcing interlining, ensuring garments maintain consistent quality, structure, and durability across various production batches. Understanding material compatibility, adhesion properties, and sustainability considerations allows procurement professionals to confidently navigate supplier options and optimize overall efficiency. With this foundation, it becomes possible to explore more detailed strategies, practical case studies, and emerging industry trends that directly impact purchasing outcomes.

While standard orders may follow basic sampling and approval, larger or more specialized requirements demand a structured methodology. The following steps provide a comprehensive approach:

Material Specification Analysis

Define precise requirements for weight, thickness, and handle.

Document preferred types (woven, nonwoven, fusible, knitted).

Include specific adhesion or bonding needs for fusible options.

Supplier Technical Consultation

Discuss potential challenges with adhesives, coatings, or finishing treatments.

Request guidance on temperature tolerances, pressing techniques, and washing performance.

Sample Testing and Evaluation

Conduct small-batch trials replicating actual production conditions.

Measure adhesion, shrinkage, colorfastness, and dimensional stability.

Collect feedback from sewing operators for practical handling insights.

Pilot Production Implementation

Run limited-scale assembly to verify integration with outer fabrics.

Record production efficiency, seam quality, and pressing outcomes.

Feedback Analysis and Adjustments

Compare performance against specifications.

Modify material choice or application method if necessary.

Bulk Procurement and Continuous Monitoring

Finalize orders with confidence.

Maintain quality audits and ongoing communication with suppliers to ensure consistency over time.

Sustainability has become a central factor in global procurement decisions. Buyers increasingly seek interlining options that minimize environmental impact without compromising performance. Key considerations include:

Recycled Fibers: Utilizing materials derived from post-consumer or post-industrial waste reduces ecological footprint.

Low-Emission Adhesives: Choosing interlining with water-based or solvent-free coatings ensures safer production environments.

Biodegradable or Compostable Materials: Offers long-term disposal solutions aligned with eco-conscious consumers.

Compliance and Certifications: Selecting suppliers adhering to recognized environmental standards supports regulatory compliance and brand integrity.

Scenario 1: Tailored Suit Production

A premium tailoring brand required interlining that maintains crisp lapels while remaining flexible. UBL supplied a woven fusible option with precise adhesive distribution, enabling consistent shape and smooth drape across hundreds of garments. Operators reported ease of stitching and minimal fabric distortion, reducing rework and enhancing efficiency.

Scenario 2: Shirt Manufacturing

Collars and cuffs demanded lightweight fusible interlining with high adhesion and soft handle. Through sample trials, procurement teams verified performance across multiple washes and pressing cycles. UBL’s solution ensured uniform results, allowing large-scale production without compromising comfort or appearance.

Scenario 3: Sportswear and Activewear

Knitted interlining provided elasticity to stretch fabrics while maintaining shape retention. Athletes benefited from garments that moved naturally, while manufacturers reduced the risk of seam tension issues. UBL’s flexible options demonstrated adaptability across diverse fabric blends.

Scenario 4: Casual Wear Production

For mass-market garments, nonwoven interlining delivered cost-effective stability. Procurement managers achieved consistent garment structure at scale, meeting quality expectations while optimizing production budgets.

Q1: How to choose the right interlining for delicate fabrics?

A1: Evaluate weight, handle, and adhesive type. Lightweight fusible or sew-in options are usually ideal for silk, chiffon, or fine cotton. Conduct sample testing to ensure no puckering occurs during pressing.

Q2: How to test fusible interlining adhesion?

A2: Apply sample to the target fabric under standard pressing conditions. Perform multiple wash cycles and dry cleaning simulations, assessing peel resistance, dimensional stability, and fabric distortion.

Q3: Can interlining improve garment longevity?

A3: Yes. Properly selected interlining prevents collapse, maintains shape, and supports seams, significantly extending wearable life.

Q4: What sustainability features should be considered?

A4: Look for recycled fibers, low-emission adhesives, biodegradable compositions, and verified certifications to ensure environmentally responsible sourcing.

Maintaining a reliable interlining supply chain is critical for operational success:

Long-Term Supplier Relationships: Build trust and collaboration to secure stable pricing, quality, and lead times.

Inventory Buffering: Keep adequate stock to avoid production delays while balancing storage costs.

Quality Audits: Periodically check batches to confirm consistency in weight, adhesion, and hand feel.

Logistics Optimization: Coordinate shipping schedules, consider customs requirements, and use reliable carriers.

Digital Tracking: Implement systems to monitor orders, shipment status, and inventory levels, enabling proactive decision-making.

Digital Printing on Interlining

Advanced techniques allow pre-marked lines or branding to be printed on support layers, improving assembly accuracy.

Performance-Oriented Materials

Stretchable, moisture-wicking, and temperature-responsive interlining options cater to sportswear and technical garments.

Eco-Conscious Materials

Recycled polyester, organic cotton, and biodegradable adhesives gain traction in global supply chains.

Customized Solutions

Brands increasingly request tailored support layers that integrate with specific fabrics and garment designs, emphasizing collaboration with suppliers like UBL.

Wide Product Range: Comprehensive options across woven, nonwoven, knitted, fusible, and sew-in categories.

Consistent Quality: Strict QC ensures uniform adhesion, handle, and weight across every batch.

Technical Expertise: Guidance in material selection, sample testing, and problem-solving during production.

Sustainability Focus: Environmentally responsible processes align with regulatory and consumer expectations.

Global Reach: Reliable logistics, timely delivery, and responsive customer support worldwide.

By combining innovation, quality assurance, and sustainability, UBL empowers procurement teams to make confident, strategic decisions.

Effective sourcing of interlining extends beyond basic material selection. It encompasses compatibility assessment, adhesion evaluation, durability testing, sustainability alignment, and structured procurement strategies. By following good practices, leveraging supplier expertise, and remaining informed of industry trends, buyers can ensure garments meet both functional and aesthetic expectations.

For procurement professionals seeking a trusted partner capable of delivering high-quality, versatile, and sustainable interlining solutions, UBL offers unmatched reliability, technical guidance, and global support. Explore our full product range and learn more about our services at interlining-factory.com .