Where Does Your Shirt’s Crisp Structure Come From?

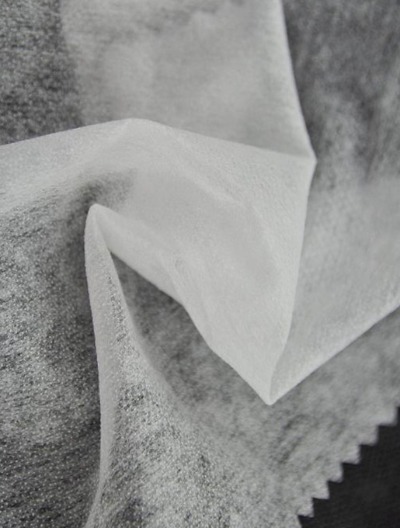

Have you ever wondered why a shirt collar holds its shape so perfectly, a pocket edge lies flat, and the front placket maintains a flawless drape without becoming wrinkled or distorted? This is the work of an unsung hero in the world of apparel manufacturing: the nylon nonwoven interlining. This unassuming material is the backbone of a garment, providing crucial support, shape retention, and stability. It ensures that clothing retains its original design and elegance even after repeated wear, washing, and ironing. Especially when dealing with delicate fabrics like silk, pure cotton, or diverse chemical fibers, choosing the right interlining is like breathing life into the garment, allowing each piece to project a lasting, timeless appeal.

The Secret Blend: Nylon and Polyester in Perfect Harmony

The exceptional performance of this interlining stems from its unique material composition. It’s not a single-fiber product but a meticulously crafted blend of 80% nylon staple fiber and 20% polyester staple fiber. This precise ratio is far from arbitrary; it’s a strategic combination designed to harness the best qualities of both materials. Nylon fibers, renowned for their incredible tensile strength and resilience, provide a robust yet lightweight structural foundation for the garment. Meanwhile, polyester fibers contribute superior durability and wrinkle resistance, enhancing the overall stability and shape-retention capabilities of the interlining. This synergistic blend, achieved through advanced carding and hot-rolling techniques, results in a nonwoven fabric that is soft and smooth to the touch, yet possesses formidable supporting power. Furthermore, this innovative process significantly reduces the interlining’s heat shrinkage rate. This is a critical feature, as it prevents the fabric from puckering or deforming during high-temperature ironing and subsequent washing, thereby safeguarding the garment’s aesthetic integrity for the long term.

The Core Technology: Double-Dot Coating and High-Performance Adhesion

The secret to this interlining’s firm bond with the outer fabric lies in its state-of-the-art double-dot coating technique. Unlike conventional single-dot or powder-scattering methods, this process creates countless tiny, uniform adhesive points across the interlining’s surface. These points act like a network of microscopic suction cups that, under heat and pressure, form a robust and lasting bond with the fabric’s fibers. This unique structure not only ensures outstanding adhesion but also preserves the fabric’s natural breathability and softness, avoiding the stiff, board-like feel that can result from inferior interlinings. The coating itself is a high-performance PA hot melt adhesive powder, specifically chosen for its exceptional resistance to both water washing and dry cleaning. This adhesive guarantees that the interlining’s bond will remain secure even after numerous laundering cycles, preventing delamination or blistering. It is this masterful fusion of advanced technology and premium materials that gives this interlining its remarkable resilience under the most rigorous conditions.

A Versatile Partner: Adapting to a Spectrum of Fabrics

The versatility of this nylon nonwoven interlining is truly remarkable. It partners seamlessly with a wide range of common garment fabrics, from the delicate drape of silk to the breathability of pure cotton, the durability of polyester, and even the unique texture of woolen fabrics. Its applications are extensive, covering crucial areas of a shirt such as the front panels, collar, cuffs, waistband, placket, and various pockets and reinforcement zones. The choice of interlining is often tailored to the specific garment section. For instance, collars require a firmer hand to maintain their crisp shape, while cuffs and waistbands need a balance of elasticity and support. Front panels, conversely, must complement the fabric’s natural drape. By offering a variety of weights and thicknesses, this interlining series can be precisely customized to meet the differing functional requirements of each garment component, providing a truly bespoke solution.

A Commitment to Quality: A Stable Journey from Production to Final Wear

The ultimate value of a high-quality interlining is reflected in the wearing experience and longevity of the finished garment. Imagine the frustration if an inferior interlining were to deform, bubble, or delaminate after the very first wash—it would severely damage the brand’s reputation and the consumer’s trust. This nylon nonwoven interlining, however, undergoes stringent quality control at every stage, from fiber blending to double-dot coating, ensuring its hallmark properties of low shrinkage, high bond strength, and superior wash resistance. This stability is a constant throughout the garment’s lifecycle, from manufacturing and finishing to the consumer’s daily use. It not only reduces the potential for costly rework during production but also guarantees a consistently excellent end product. Therefore, when evaluating an interlining, it’s crucial to look beyond its surface feel and adhesive strength and delve into the underlying technology and material science. This is the true measure of whether an interlining can serve as the reliable, unseen skeleton for a piece of high-quality apparel.

English

English Español

Español Türk

Türk 简体中文

简体中文