Enhancing Every Garment

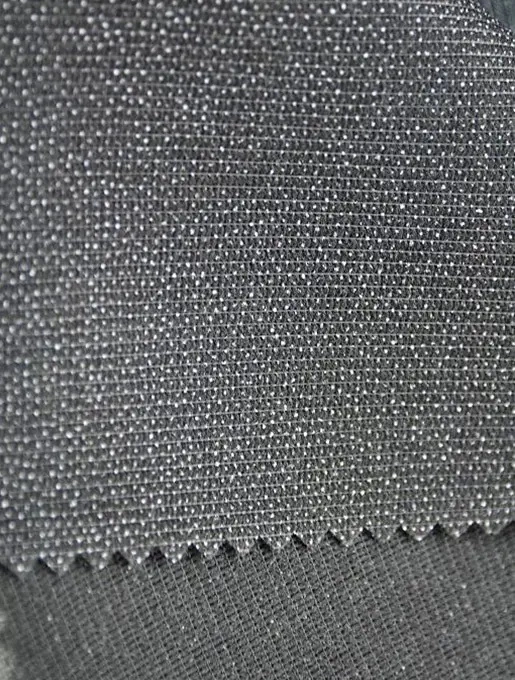

Tricot interlining, also known in Chinese as经编衬布, is an indispensable auxiliary material in textile and garment manufacturing. Its name is derived from its unique production method: "tricot," a warp-knitting technique that creates a stable longitudinal structure. Unlike traditional woven interlining, tricot interlining offers superior elasticity and drape.

This material is typically fused or sewn onto the back of a fabric. Its primary purpose is to provide extra support, shaping, and stability. It prevents the fabric from deforming during cutting or sewing and enhances the final product's texture and durability. Whether a suit or shirt collar needs a crisp, structured feel, or a light dress or knitwear requires an elegant drape, tricot interlining plays a vital role. It acts as the garment's "skeleton," giving the clothing better form and feel without compromising the fabric's original characteristics.

Tricot interlining is not a single product but can be divided into several types based on its characteristics and uses. Understanding these types helps in choosing the most suitable interlining for different projects.

Warp knit interfacing is a precise technical term for tricot interlining. The warp-knitting process gives the interlining distinct advantages:

This is the most common type of tricot interlining. Its core feature is a coating of hot-melt adhesive on the back.

Although fusible interlining is popular, sew-in interlining is still the preferred choice in certain situations.

Tricot interlining, with its unique softness and elasticity, plays an indispensable role in various garment and textile productions. Its versatility allows it to adapt to different needs, from everyday wear to high-end custom apparel.

Lightweight interfacing fabric is particularly suitable for projects where the natural drape of the fabric needs to be preserved. Its light weight ensures the clothing's fluidity and comfort while providing necessary structural support.

| Application Area | Fabric Type | Main Function |

|---|---|---|

| Collar, Cuffs | Chiffon, Silk, Georgette | Maintain shape, prevent deformation |

| Hem, Skirt Bottom | Knits, Thin Cotton | Enhance drape, improve stability |

| Pocket Edges | Any Lightweight Fabric | Prevent stretching, increase durability |

As the most common type, tricot fuse excels in projects requiring quick and secure bonding due to its heat-fusing property.

The widespread application of tricot interlining proves its importance in improving garment quality and production efficiency. Whether it's used to increase the stability of a lightweight fabric or to provide support for a shaped area, it is a powerful tool for designers and tailors.

Correctly choosing and using tricot interlining is key to a successful project. The wrong choice or application method can lead to bubbling, stiffness, or deformation of the fabric, affecting the quality of the final product.

When choosing interlining, the most important rule is that the “interlining should be lighter than the fabric.” This ensures that the interlining won't alter the fabric's original drape and feel while still providing sufficient support.

| Fabric Type | Recommended Tricot Interlining Characteristics | Reason |

|---|---|---|

| Lightweight Fabrics (chiffon, silk, thin cotton) | Lightweight, soft, elastic, both fusible and sew-in options are suitable | Preserves the fabric's lightness and flow, provides subtle support, and prevents wrinkling and deformation. |

| Medium-Weight Fabrics (cotton, linen, some knits) | Medium-weight, fusible, with good adhesive properties | Provides sufficient structure, suitable for shaping areas like shirt collars and jacket facings. |

| Heavyweight Fabrics (tweed, denim) | Medium to heavyweight, fusible, with strong adhesion | Provides extra support for heavy fabrics, preventing stretching or shifting during the sewing process. |

The method of using tricot interlining depends on whether it's fusible or sew-in.

Mastering these selection and usage tips can greatly improve your production efficiency and the quality of your finished products, allowing tricot interlining to truly play its role as an "invisible" helper.

Tricot interlining is far more than a simple piece of fabric; it plays a vital "unsung hero" role in the textile and garment industry. Its value is reflected on multiple levels, fundamentally enhancing the quality, appearance, and durability of the finished product.

The core value of tricot interlining lies in its versatility:

From a technical perspective, the value of tricot interlining lies in its perfect balance of strength and flexibility. It can provide the required support for the fabric while maintaining its inherent softness and elasticity. This balance is key to its prominence among numerous textile auxiliaries.

The value of tricot interlining is ultimately felt by the consumer. A garment made with high-quality tricot interlining not only has a better texture and a more comfortable feel but also retains its original shape for longer, truly achieving the perfect combination of art and function in clothing.

Jiaxing Rainbow (UBL) Interlining Co., Ltd has extensive experience in professional design, development, and production. We are always focusing on the research of high technology in interlining and upgrading our products based on changing customer demands. With our 19 years of experience and technology, UBL can provide the best products and services to our customers, including customizing different types and characteristics of tricot interlining according to specific requirements.

UBL is one of the initial double-dot coating manufacturers in China, having seized the opportunity to upgrade our production equipment in 2000 to become a leader in the industry. We currently have a monthly production capacity of 6 million meters of all kinds of double-dot interlining. Our fusible Tricot interlining uses advanced double-dot coating technology, ensuring superior adhesive strength. This allows the interlining to bond perfectly with the fabric, preventing bubbling and providing more lasting and stable support.

With our concept of “Practical, professional and forge ahead with determination,” UBL is committed to creating the most valuable enterprise through technology innovation and promoting the development of society. If you have any questions or needs regarding our Tricot interlining products or other interlinings, please feel free to contact us. Our professional team will be dedicated to providing you with solutions and technical support.