Enhancing Every Garment

In the world of garment creation, what we see is only half the story. Behind the elegant drape of a coat, the crisp collar of a shirt, and the structured silhouette of a dress lies an unsung hero: interlining. This foundational material acts as the hidden skeleton of apparel, providing shape, support, and durability that transforms simple fabric into a finished, high-quality garment.

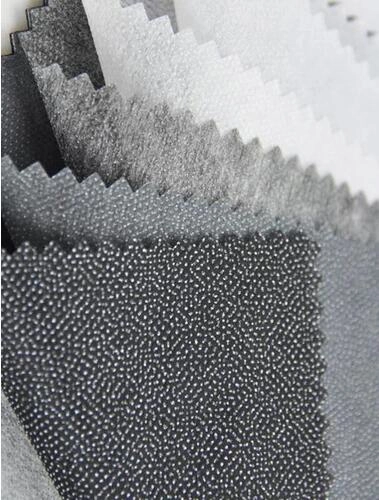

Among the various materials used for this crucial purpose, nylon interlining stands out as a premier choice for designers and manufacturers. Its unique combination of exceptional strength, remarkable lightness, and inherent flexibility makes it an indispensable component for a wide range of applications. From adding subtle body to delicate blouses to providing robust reinforcement in technical outerwear, nylon interlining delivers performance where it counts.

This guide delves into the essential role of nylon interlining, exploring its different forms, the advanced technology behind it, and its practical applications. Understanding its properties and uses is key to making informed decisions that elevate the quality, functionality, and longevity of any sewn product.

Nylon interlining is a specific category of textile material, primarily made from nylon fibers, which is engineered to be fused or sewn between the outer fabric and the lining of a garment. Its primary purpose is to provide internal support, control, and reinforcement, thereby enhancing the structure, shape, and durability of the final product. Unlike the main fabric, its value lies not in its visibility but in its performance characteristics, which directly influence the garment's aesthetics, handle, and longevity.

Manufacturing Process: This type is produced by forming a web of nylon fibers held together by chemical, thermal, or mechanical means.

Characteristics & Performance: Isotropic nature, cost-effectiveness, less drape than other types.

Typical Applications: Shirt collars and cuffs, pocket flaps, and some jacket facings.

Manufacturing Process: Woven varieties use traditional loom weaving, while knitted types use interlocking loops.

Characteristics & Performance: High strength, directional properties, superior drape and flexibility.

Typical Applications: Suit canvases, structured blazers, dress bodices, and stretch garments.

Process Overview: Composite material with heat-activated adhesive coating.

Revolutionary Advantages: Dramatically increases production speed and ensures consistent bonding quality.

The Role of Nylon: Provides lightweight strength, excellent recovery, and soft handfeel.

| Property | Nonwoven | Woven | Knitted | Notes |

|---|---|---|---|---|

| Production Speed/Cost | High / Low | Low / Medium-High | Medium / Medium | Nonwoven is most cost-effective |

| Isotropic | Yes | No | Usually No | Uniform properties in all directions |

| Strength | Medium | Very High | High | Woven offers greatest sheer strength |

| Drape | Fair | Good | Excellent | Knitted conforms best to body curves |

| Elasticity | Low | Low | Very High | Knitted ideal for stretch fabrics |

Double dot coating is widely regarded as a superior and advanced process, particularly valued for preserving the natural characteristics of the outer fabric.

Precise manufacturing process where two distinct layers of thermoplastic adhesive are applied in a controlled dot pattern.

| Property | Double Dot | Powder Dot | Continuous Paste | Notes |

|---|---|---|---|---|

| Softness | Excellent | Good | Poor/Stiff | Discontinuous dots preserve flexibility |

| Anti-Bleeding | Very High | High | Low | Isolated dots prevent strike-through |

When to Choose Sewing Interlining: Heat-sensitive fabrics, traditional craftsmanship, very heavy fabrics.

When to Choose Fusible Interlining: Modern ready-to-wear, smooth appearance requirements, production efficiency.

Suits & Structured Blazers: Medium-weight woven or knitted varieties

Dresses & Blouses: Lightweight nonwoven or knitted types

Outdoor & Performance Wear: Woven or nonwoven with high strength

Nylon interlining stands as a fundamental and versatile component in modern textile manufacturing. Its unique combination of properties makes it indispensable for providing structure, support, and enhanced performance across various applications.

Superior bond strength, excellent wash resistance, and exceptional handfeel preservation.

Jiaxing Rainbow (UBL) Interlining Co., Ltd specializes in producing high-performance interlinings with these advantages.

Nylon excels in lightweight strength, elasticity, and softness compared to other materials.

Absolutely. Its strength-to-weight ratio and flexibility make it ideal for technical applications.

Jiaxing Rainbow (UBL) Interlining Co., Ltd, founded in 1995, is a leading interlining producer in China with focus on innovation and quality.